Product

Industwin empowers you to unlock the full potential of your turbines, ensuring they operate at peak performance for years to come.

IndusTwin: A Digital Twin Revolutionizing Turbine Maintenance

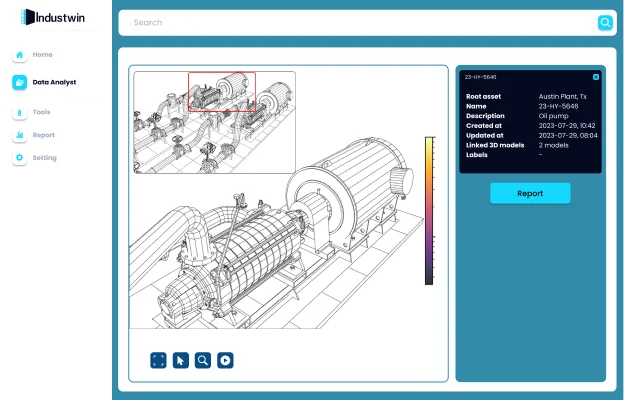

Industwin is a pioneering digital twin solution designed to transform turbine maintenance. It leverages advanced technologies like IoT sensors, artificial intelligence, and cloud computing to overcome the shortcomings of traditional predictive maintenance (PdM) methods. Unlike PdM, which relies on skilled analysts and time-consuming reports, Industwin automates data collection, analysis, and reporting, minimizing human error and streamlining operations. Industwin provides real-time health monitoring of turbines, allowing for early detection of anomalies and potential issues. This empowers users to move from reactive maintenance to a predictive approach, leveraging AI-powered insights for informed decision-making. Additionally, Industwin fosters improved collaboration through a cloud-based platform offering real-time access to turbine health data from any location. Overall, Industwin provides a scalable solution for enhanced efficiency, reduced downtime, and significant cost savings for industries reliant on turbines.

Real-Time Data at Your Fingertips

Industwin harnesses the power of the Internet of Things (IoT) by strategically deploying sensors focusing on vibration measurement. This continuous stream of real-time data provides a comprehensive picture of the turbine's health, enabling early detection of anomalies and potential issues. Imagine having a constant pulse on your turbine's condition, allowing you to address problems before they snowball into costly failures proactively.

Scalable Solution for Large-Scale Deployments

Industwin's cloud-based nature makes it highly scalable. It can effectively manage a large fleet of turbines across geographically dispersed locations, providing a centralized view of their health and maintenance needs. Industwin scales with your operations, making it a future-proof solution for managing a growing turbine fleet, regardless of their physical distribution.

Minimizing Errors and Rework for Enhanced Efficiency

By automating data collection, analysis, and reporting, Industwin reduces the risk of human error and the need for rework. This translates to a more reliable and efficient maintenance process, reducing downtime and associated costs. Industwin takes the guesswork out of turbine maintenance, ensuring tasks are completed correctly the first time, saving you valuable time and resources.

AI Insights Powering Maintenance Decisions

At the heart of Industwin lies Artificial Intelligence's (AI) power. Sophisticated AI algorithms analyze the massive datasets the sensors collect, identifying patterns and predicting potential failures with high accuracy. This eliminates dependence on limited human expertise for data analysis, ensuring faster, more reliable insights. Industwin empowers you to move beyond reactive maintenance to a genuinely predictive approach, making informed decisions based on data-driven intelligence.

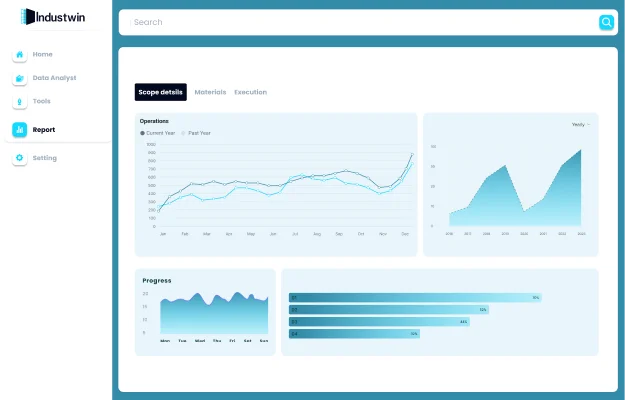

Cloud-Based Accessibility for Streamlined Operations

Industwin operates on a secure cloud platform, eliminating the need for cumbersome technical reports. A user-friendly dashboard provides real-time access to the health status of all turbine components, accessible from any location. This translates to immediate decision-making and faster response times to potential issues. Imagine having a central hub for all your turbine health data, accessible to your team members whenever and wherever they need it. Industwin fosters streamlined operations and improved collaboration between maintenance personnel and management.